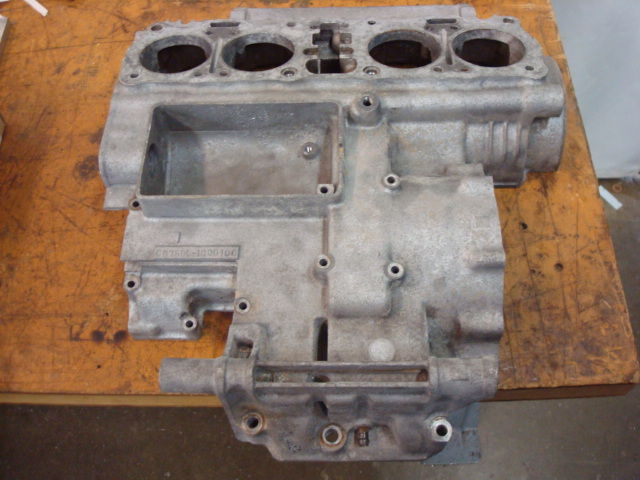

I got my cases, crank and oil tank back from the hot tank and ultrasonic cleaning. They didnít come out as fresh looking as I hoped but they are definitely cleaner and all the holes look great and the inside of the tank looks good. Iím satisfied that all the oil galleries are clean.

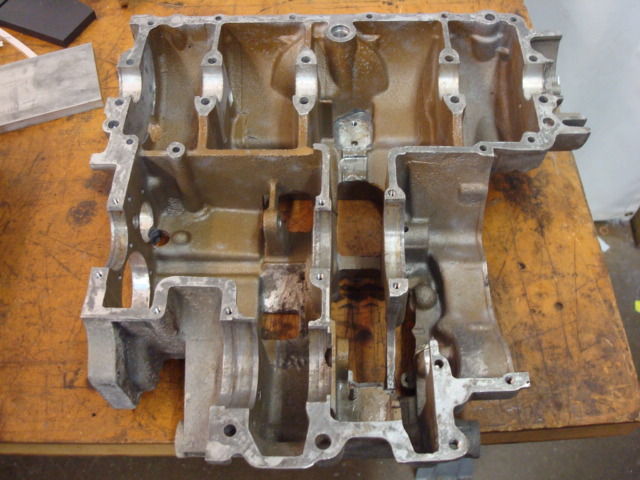

You can see that the inside of the cases still has that brownish, stained look. But itís nice to be able to handle them without having to wipe my hands off afterwards.

I do have another issue though. Upon closer inspection of the oil filter housing surface, there is some pitting at the bottom.

Hereís a closer shot. Hard to see it well. Iím obviously concerned about the o-ring sealing properly. My first thought was to apply a thin layer of JB Weld with a putty knife to fill in the pits and then flat file it to make sure itís smooth. Anyone else have this issue? Any thoughts?

Mark B1969 CB750 sandcast #97 restored - Sold

Restoration thread link1969 CB750 sandcaxt #576 - Sold

1969 CB750 sandcast #1553 - Sold

1969 CB750 sandcast #1990 - Sold

1969 CB750 sandcast #5383 restored - Sold

Restoration thread link1970 CB750 K0 restored - Sold

2010 H-D Tri Glide Ultra Classic (Huh?)